machining surface finish chart pdf

SURFACE FINISH CHARTS Surface Finishing Mechanical Polishing and ElectroPolishing Machining and mechanical polishing Mechanical polishing or machining leaves numerous surface scratches which cause areas of differing electrical potential due to surface stresses. Today Yide Casting will introduce the conversion in China and USA standard for Ra um Ra micro inch Rz um RMS and finish degree and the related finish.

Complete Surface Finish Chart Symbols Roughness Conversion Tables

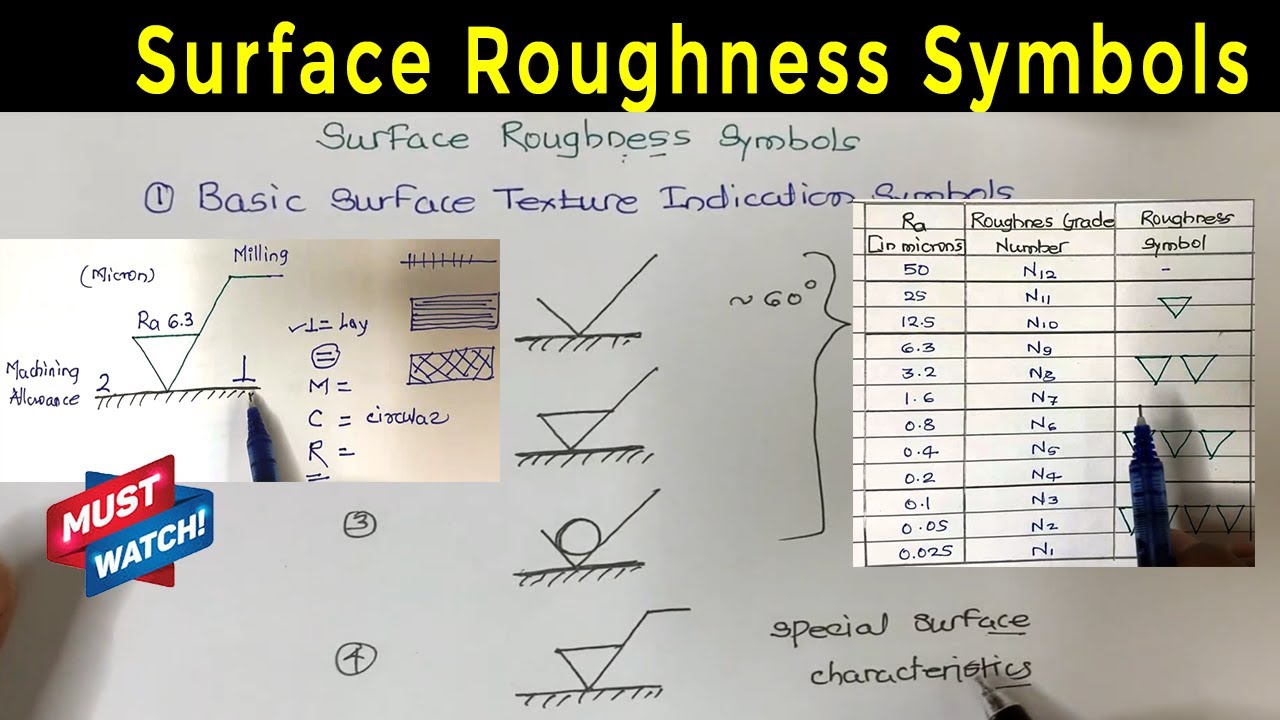

Is placed around the surface symbol as shown in Fig.

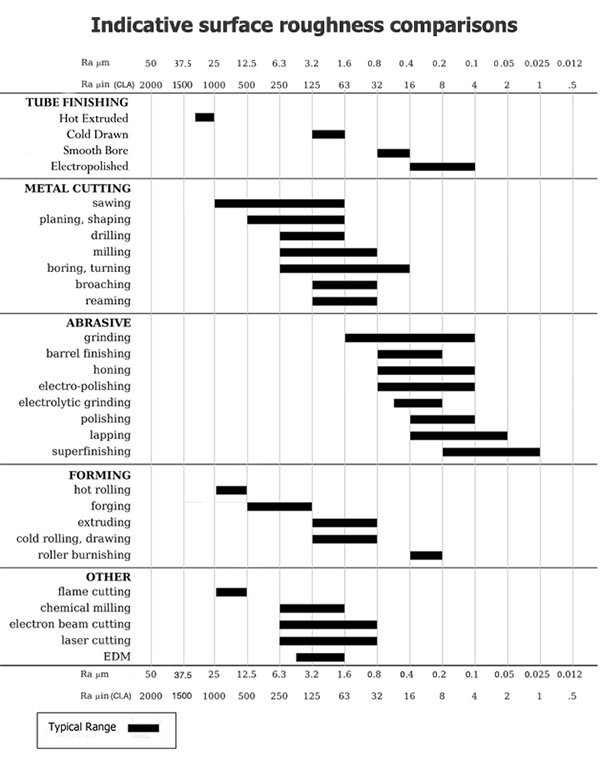

. Machining Drilling 008 -003mm Milling 008mm Turning 005mm Abrasive processes Grinding 0008mm Lapping 0005mm Surface finish roughness Casting Die Casting Good 1-2µm Investment Good 15-3 Sand Casting Poor 12-25 Metal forming Cold rolling Good 1-3 Hot rolling Poor 12-25 Machining. Surface finish ra µin 2ra feed rate8 x tool nose radius x 317500. SURFACE FINISH CROSS REFERENCE CHART Common USA name.

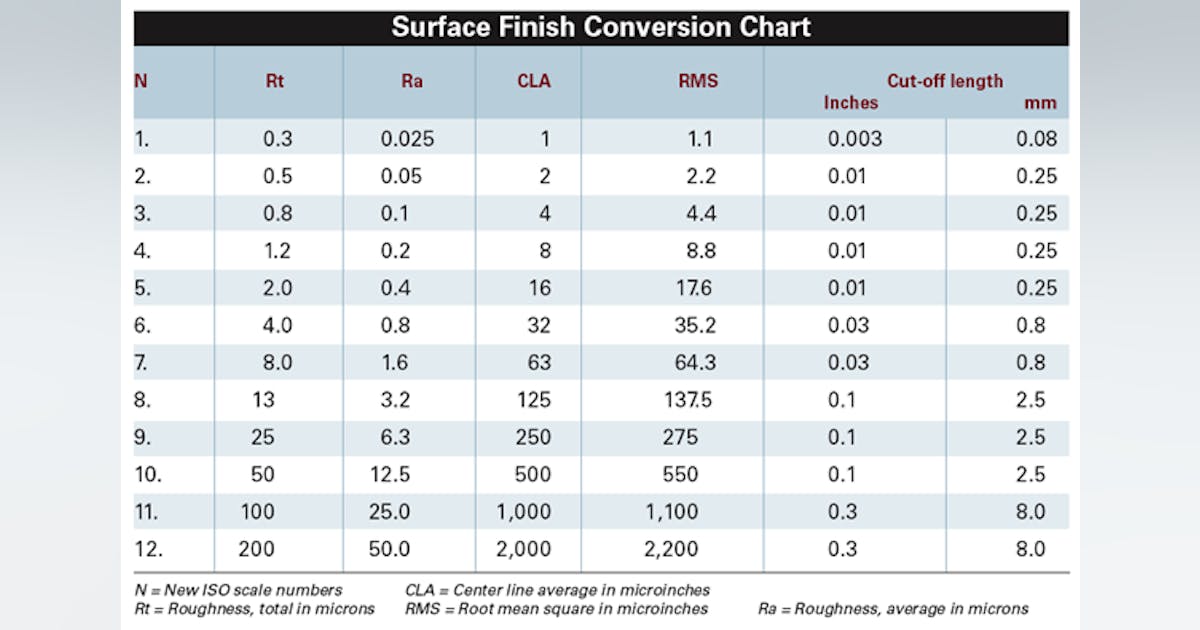

Many investigations have been carried out on. In this section theres a table for the surface finish conversion chart. Surface roughness value normally at right angles to the lay of the machining marks.

Surface finish rms µin rms ra x 111. Notice the workbench changes but the part stays the same. This type of chart gives the average finish for a particular process.

Infeed rate inmin h. Height UEFCO ISO 1302 MCC 0006 025 N01 0012 05 005 005 N0 0025 1 025 01 01 N1. Machining Surface Finish Chart Comparator Method Degree Ra Rz RMS The surface finishes smooth degree is an important requirement as for the machining to steel and iron castings.

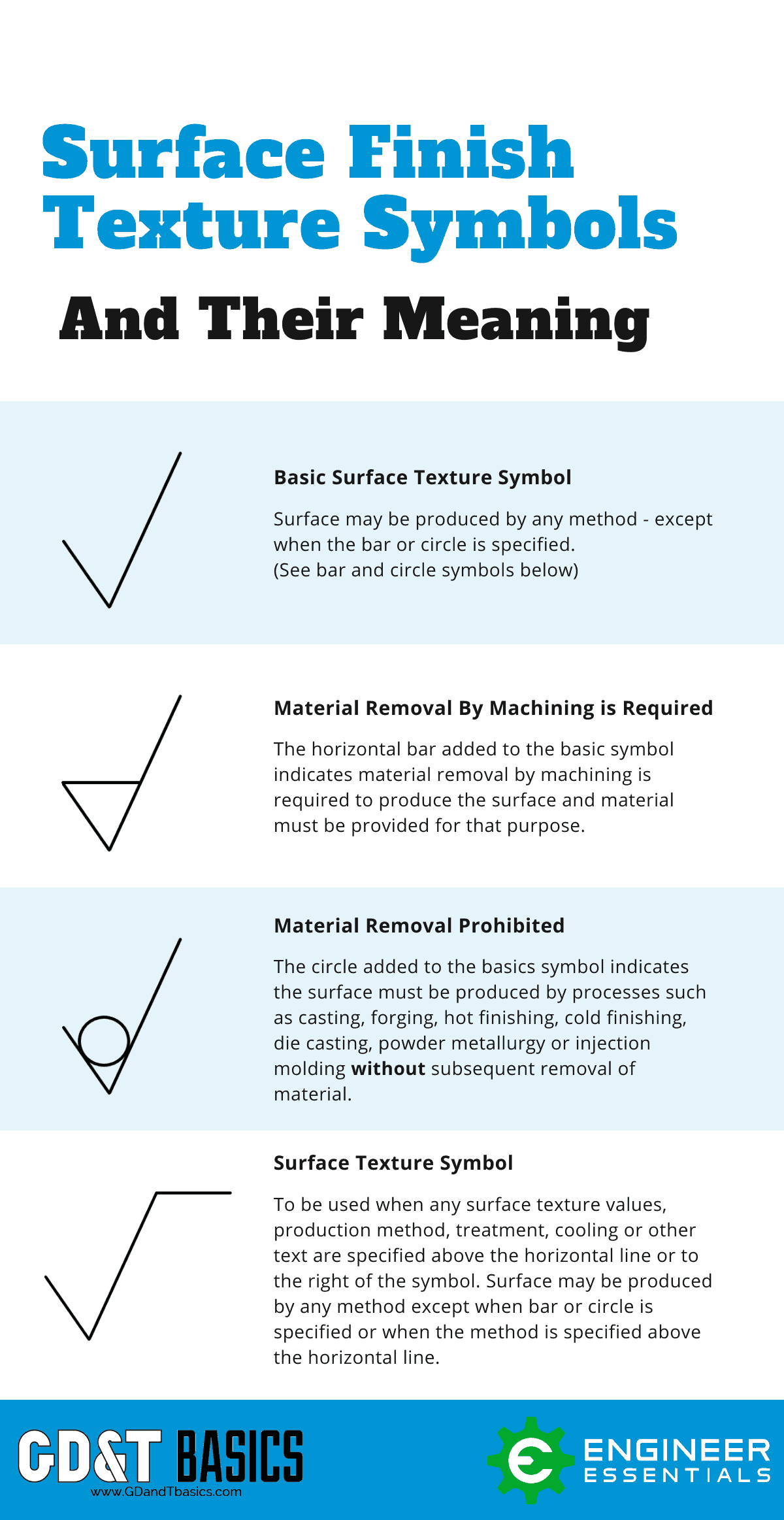

Before we get on with Surface Finish Symbols lets understand how Surface Finish is defined. The following is the conversion chart is from dandong foundry for Ra um Ra micro inch Rz um RMS and finish degree in China and USA including the related finish methods. Horsepower required at machine spindle motor hp.

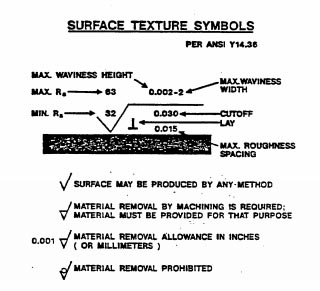

22 rows As for machining to iron and steel castings the surface finish smooth degree is also an important requirement. Roughness average values machining allowance basic surface texture symbol roughness average values a. Properties may contribute to surface porosity inclusions and residual elements.

Red Wing MN 55066 PH. There are different processes in examining the machining surface finish chart. As for machining to iron and steel castings the surface finish smooth degree is also an important requirement.

ROUGHNESS COMPARISON 1-2 2-3 2-3 9-10 10-12 25-28 38-42 10-12 26-32 190-930 CURRENT SPI FIINSH NUMBERS 3 Diamond Buff 6 Diamond Buff 15 Diamond Buff 600 Grit 400 Grit 320 Grit 600 Stone 400 Stone 320 Stone 11 Glass Bead 240 Aluminum Oxide Blast Aluminum Oxide Blast 83 02 03. This paper aims at presenting the effective parameters on surface roughness in machining process. It compares different production methods using the same material and can differentiate the surface roughness.

Removal of Material by Machining is Required Surface Symbol IExamples Symbol Meaning Illustration A surface roughness value cut-off value or reference length processing method grain direction surface undulation etc. Complete Guide to Surface Finish Symbols Charts RA RZ Measurements and Callouts Definition of Surface Finish. 1 Positions of Auxiliary Symbols a.

Machining marks very obvious. Machining surface finish chart comparator method degree Ra Rz RMS. In addition inherent material.

4079 Pepin Ave. SURFACE ROUGHNESS CONVERSION CHART Mactech Inc. However the most robust is the use of the surface finish conversion chart.

An auxiliary symbol indicating a surface roughness value cut-off value or reference length machining method grain direction surface undulation etc. If youre trying to decide on the best manufacturing process you can use a surface roughness chart. AGIE-CHARMILLES EDM SURFACE FINISH CROSS REFERENCE CHART Price 325 each plus 4 service charge if use of a Credit Card.

Specify in microinches micrometers or roughness grade numbers. Surface Finish Measurements and Charts. Are indicated around the surface symbol as.

In min x matl power constant spindle drive efficiency ii. Cutting time t t loc. As a result it becomes challenging to pick the best process.

Height UEFCO ISO 1302 MCC 0006 025 N01 0012 05 005 005 N0 0025 1 025 01 01 N1. 651-388-7117 TOLL FREE. CATIA Surface Machining CATIA V5R13 Roughing Operations Page 76 Wichita State University Now that you have a few prismatic machining operations you are ready to integrate the surface machining tools.

An electropolished surface is essentially balanced. Use Surface Roughness Charts. Maximum and minimum roughness average values specify in microinches micrometers or roughness grade numbers.

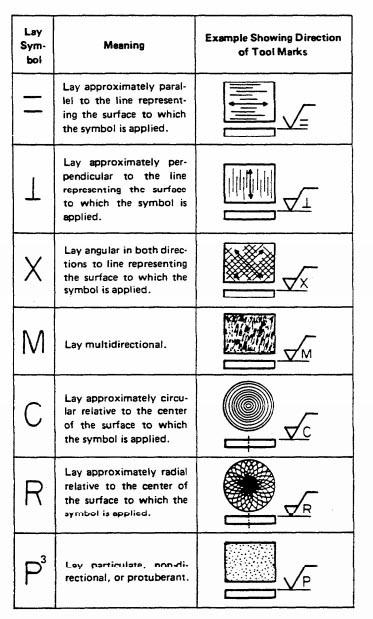

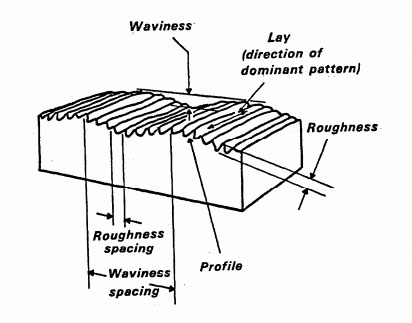

The following is the conversion chart is from dandong foundry for Ra um Ra micro inch Rz um RMS and finish degree in China and USA including the related finish methods. Engineering prints call out a great many things in their attempt to make sure the part that gets made matches the designers intent. All manufactured components have some form of surface texture which has elements of lay the machining or forming pattern surface roughness and waviness.

Switch to the Surface Machining workbench. ROUGHNESS CONVERSION CHART Ra μm ISO 468 e 4287 AA μinch USA ASA B461 Centre Line Average CLA μinch UK BS 1134 Rt μm Germany Rz μm JIS average in 10 points Ry μm max. Agiecharmilles edm surface finish cross reference chart agie charmilles edm finish scale ra - micro-meter ra - micro inches rms -2 08 314 390 -1 09 354 440 0 10 394 490 1 11 433 550 2 12 472 590 3 14 551 690 4 16 629 79 0 5 18 709 890 6 20 787 990.

Surface Finish Conversion Chart. The measured profile is the profile resulting from scanning the actual profile with a probe which mechanically filters this profile due to the probe tip radius r tip and if fitted by the skid of the probe system. ROUGHNESS CONVERSION CHART Ra μm ISO 468 e 4287 AA μinch USA ASA B461 Centre Line Average CLA μinch UK BS 1134 Rt μm Germany Rz μm JIS average in 10 points Ry μm max.

Surface imperfections such as cracks. Surface Finish Metrology Tutorial Author. Maximum waviness height rating b specify in inches or millimeters.

SPI MOLD FINISH GUIDE 1-800-215-MOLD.

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Surface Finishing Basics Fractory

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Surface Finish Conversion Tips American Machinist

The Basics Of Surface Finish Gd T Basics

Surface Finish Conversion Chart Ra To Rz Rz To Ra Surface Texture Conversion 447 426 Of New S Surface New Surface Surface Textures

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Finish Symbols Surface Surface Finish

Surface Roughness Conversion Chart Engineers Edge Surface Roughness Chart Surface Finish Symbols

Machining Surface Finish Chart Conversion Comparator Method Degree Ra Rz Rms

Surface Roughness Geometrical Dimensioning Tolerancing Gd T Surface Roughness Surface Geometric

Surface Finish Quality Ra Rz Rt Surface Roughness Measuring Finish

Complete Surface Finish Chart Symbols Roughness Conversion Tables

The Basics Of Surface Finish Gd T Basics

Pin By Ray On Jic Jis Bsp Din Iso Sae Hydraulic Fittings Drawing Size Chart Surface Roughness Surface Size Chart

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Complete Surface Finish Chart Symbols Roughness Conversion Tables